Managing noise and vibration in equipment involves identifying common causes like misalignments, loose parts, or worn bearings. You can monitor issues with sensors and regular inspections to catch problems early. Implement design solutions such as damping materials and isolation mounts, and perform maintenance like tightening bolts and replacing worn parts. Modern technologies, including smart sensors and AI security, enhance control efforts. Keep exploring to discover advanced techniques that help keep your equipment safe, efficient, and reliable.

Key Takeaways

- Regularly monitor noise levels and vibrations using sound meters and accelerometers to identify abnormal patterns early.

- Perform routine maintenance, including tightening bolts, replacing worn bearings, and cleaning debris to prevent excessive noise and vibration.

- Implement vibration isolators, dampers, and structural reinforcements to minimize transfer and resonance effects.

- Use targeted noise control measures like sound enclosures and absorption materials tailored to specific equipment.

- Incorporate advanced technologies such as AI security, IoT sensors, and data analytics for predictive maintenance and enhanced management.

Common Causes of Noise and Vibration in Equipment

Many equipment issues that lead to noise and vibration stem from mechanical imbalances or misalignments. When parts are unevenly worn or improperly installed, they create uneven forces that cause vibrations. Loose bolts, worn bearings, or damaged belts also contribute, allowing components to shift or wobble during operation. Misaligned shafts or pulleys generate excessive stress, producing abnormal noise and vibration. Additionally, debris or dirt build-up inside moving parts can disrupt smooth operation. These issues often result from poor maintenance, improper installation, or normal wear over time. Recognizing these common causes helps you identify potential problems early. Addressing imbalances, tightening loose parts, and maintaining alignment are essential steps to reduce noise and vibration, ensuring your equipment runs smoothly and efficiently. Regularly inspecting dynamic balance of rotating parts can prevent many of these issues before they escalate.

Impact of Noise and Vibration on Workplace Safety and Productivity

Noise and vibration from equipment can considerably impact workplace safety and productivity. Excessive noise may cause hearing loss, reduce communication, and increase fatigue, leading to accidents. Vibration can cause musculoskeletal disorders and impair operator precision. To safeguard your environment, consider these factors:

Managing equipment noise and vibration is vital for workplace safety and efficiency.

- Decreased alertness: Persistent noise dulls awareness, increasing accident risk.

- Reduced efficiency: Vibrations hinder focus and manual dexterity, slowing work.

- Health issues: Long-term exposure may cause hearing damage and physical ailments.

- Employee morale: Uncomfortable working conditions lower motivation and satisfaction.

Implementing inspirational quotes about fatherhood can foster a positive attitude among staff working in challenging conditions.

Managing these impacts requires understanding their effects and implementing mitigation measures, ensuring safety and productivity are maintained in your workplace.

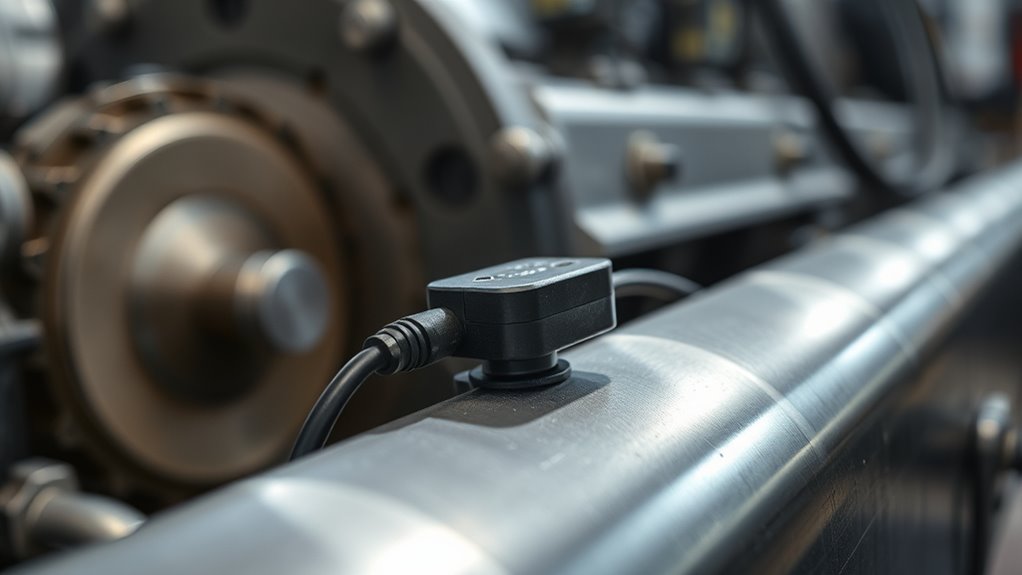

Techniques for Monitoring and Diagnosing Noise and Vibration Issues

Effective monitoring and diagnosing of noise and vibration issues are essential steps in maintaining a safe and efficient workplace. You should start by using sound level meters and accelerometers to measure noise and vibration levels accurately. Regular inspections help identify abnormal patterns indicating underlying problems. Data collection allows you to analyze trends over time, pinpointing when issues arise. Portable diagnostic tools enable on-the-spot assessments of machinery while running. Vibration analysis software can detect specific frequency patterns associated with faults, such as imbalance or misalignment. Combining these techniques helps you quickly identify the root causes of noise and vibration problems. Understanding equipment maintenance plays a critical role in preventing issues before they become costly repairs. Prompt diagnosis guarantees you can take targeted corrective actions before issues escalate, reducing downtime and preventing equipment damage.

Design and Engineering Solutions to Minimize Unwanted Vibrations

To minimize unwanted vibrations through design and engineering, you need to incorporate strategies that reduce the sources and transmission paths of vibrations. Start by optimizing component placement to prevent resonance amplification. Use damping materials or isolators to absorb vibrations before they spread. Implement stiffening techniques, like bracing or reinforcement, to minimize flexing. Ultimately, design for balanced loads and symmetry to prevent uneven stresses.

Consider these solutions:

- Incorporate vibration isolators or mounts to decouple equipment from mounting surfaces.

- Use damping materials within machinery enclosures to absorb energy.

- Reinforce structural elements to prevent flexing and resonance.

- Design symmetrical and balanced assemblies to evenly distribute loads and avoid vibrational imbalances.

Implementation of Noise and Vibration Control Measures

Implementing practical control measures is key to reducing noise and vibration levels in equipment. You should start by identifying major noise sources and applying targeted solutions, such as installing sound enclosures or damping materials. Proper maintenance, like tightening bolts and replacing worn parts, also helps minimize vibrations. Using isolation mounts can prevent vibrations from transferring to surrounding structures. Consider the environment and select measures appropriate for your specific setup. To guide your efforts, review the table below outlining common measures, their applications, and benefits: trustworthiness of Patchology.

Innovative Technologies for Noise and Vibration Suppression

Innovative technologies like active noise cancellation and smart vibration damping are changing how you control equipment noise and vibrations. These solutions respond in real-time to disturbances, providing more effective suppression. Exploring these advancements can help you optimize your noise and vibration management strategies.

Active Noise Cancellation Techniques

Active noise cancellation (ANC) techniques have revolutionized how industries suppress unwanted sound and vibrations. By using sophisticated algorithms and sensors, ANC systems generate anti-noise signals that directly cancel out noise at its source. These systems analyze sound waves in real-time, adjusting their output to effectively reduce noise levels. You can implement ANC in various equipment, from industrial machinery to consumer devices, to improve comfort and performance. Consider these key aspects:

- Microphone Arrays: Capture ambient noise accurately for precise cancellation.

- Digital Signal Processing: Analyze sound data and generate anti-noise signals swiftly.

- Adaptive Algorithms: Continuously optimize cancellation based on changing noise profiles.

- Feedback and Feedforward Designs: Enhance effectiveness by combining different cancellation strategies.

- Incorporating Bitcoin IRA insights can aid in understanding how to diversify and optimize investment strategies for long-term stability and growth.

Utilizing ANC enables you to maintain quieter, more efficient equipment environments.

Smart Vibration Damping Solutions

Smart vibration damping solutions leverage advanced materials and sensor technologies to actively monitor and reduce vibrations in equipment. You’ll find these systems use real-time data from sensors to identify vibration patterns and automatically adjust damping mechanisms. By integrating smart materials like piezoelectric or magnetorheological components, the solutions dynamically absorb or redirect vibrations, preventing them from propagating. This approach minimizes noise and mechanical stress, extending equipment lifespan. You can customize these systems to suit specific machinery, optimizing performance and comfort. Installing smart damping solutions is straightforward and often involves minimal modifications. With continuous feedback and adaptive control, you gain improved vibration suppression, reduced maintenance costs, and enhanced operational stability. Additionally, incorporating AI security technologies ensures that these systems are protected against cyber threats, maintaining their reliability and performance. These innovative technologies represent a significant step forward in noise and vibration management.

Frequently Asked Questions

How Does Equipment Age Influence Noise and Vibration Levels?

As equipment ages, noise and vibration levels tend to increase because parts wear down, loosen, or become misaligned. You might notice more rattling or louder operation as components deteriorate. Regular maintenance helps, but over time, aging equipment requires more attention to keep noise and vibrations in check. Keeping an eye on wear and replacing worn parts promptly can minimize these issues and prolong your equipment’s lifespan.

Can Operator Training Reduce Noise and Vibration Issues?

Yes, operator training can reduce noise and vibration issues. When you’re well-trained, you learn to operate equipment correctly, avoiding actions that cause excessive noise or vibrations. Proper techniques, such as correct handling and timely maintenance, help minimize these problems. Your awareness and skills directly impact equipment performance, leading to a quieter, smoother operation. Investing in your training not only improves safety but also extends equipment lifespan and reduces repair costs.

What Are the Long-Term Health Effects of Exposure to Equipment Noise?

Prolonged exposure to equipment noise can lead to long-term health issues like hearing loss, tinnitus, and increased stress levels. You might also experience cardiovascular problems, sleep disturbances, and reduced concentration. It’s vital to use hearing protection and limit exposure time. Over time, these health effects can become severe, impacting your quality of life. Taking precautions now helps protect your hearing and overall well-being in the long run.

How Do Environmental Conditions Affect Vibration Management Strategies?

Environmental conditions substantially impact your vibration management strategies. You need to take into account temperature fluctuations, humidity, and dust, as they can alter equipment performance and vibration levels. For example, high humidity may cause corrosion, increasing vibration risks, while extreme temperatures can affect material properties. By monitoring these conditions carefully, you can adjust maintenance schedules, install protective measures, and select suitable equipment to minimize vibration issues and extend equipment lifespan.

Are There Regulatory Standards Specific to Vibration in Different Industries?

Are there regulatory standards specific to vibration in different industries? Yes, many industries have standards you need to adhere to. For example, in construction, OSHA sets limits on workers’ exposure to vibration, while in manufacturing, ISO standards help guarantee equipment doesn’t exceed safe vibration levels. You must stay informed about these regulations to protect workers, ensure safety, and avoid penalties. Following industry-specific standards helps you maintain compliance effectively.

Conclusion

By understanding the causes and impacts of noise and vibration, you can take proactive steps to improve safety and efficiency. While technical solutions and innovative technologies offer powerful tools, true effectiveness comes from your commitment to proper monitoring and thoughtful design. Noise and vibration may be inevitable, but with the right approach, they don’t have to dominate your workspace. Instead, they can become manageable challenges, allowing you to focus on what truly matters—performance and well-being.