To guarantee anti-entrapment and VGB compliance at your basin, you need to understand the hazards, install approved drain covers, and incorporate multiple safety devices like automatic shutoffs and vents. Regular inspections, maintenance, and staff training are essential to keep systems safe and compliant with evolving regulations. Keeping detailed records and collaborating with experts help you stay ahead of safety standards. Continuing to explore these areas will give you key insights to enhance your basin’s safety.

Key Takeaways

- Ensure drain covers meet VGB performance standards and are properly installed to prevent entrapment hazards.

- Install multiple, independent safety devices such as automatic shut-off systems and venting mechanisms.

- Conduct regular inspections and maintenance to detect and address wear, damage, or improper installation.

- Maintain compliance documentation and stay updated on evolving regulations and safety standards.

- Incorporate risk assessments and continuous safety upgrades to uphold anti-entrapment measures at the basin.

Understanding Entrapment Hazards in Water Facilities

Understanding entrapment hazards in water facilities is essential because these dangers can pose serious risks to swimmers and patrons. Entrapment occurs when a person’s body, hair, or limbs become trapped by powerful suction or mechanical components. Common hazards include drains, main drains, or suction outlets that are improperly designed or maintained. If these devices lack proper safety features, you risk being pulled underwater or trapped against the pool floor or walls. Recognizing potential entrapment points helps you understand why safety regulations exist. These hazards can lead to injuries, drownings, or even fatalities if not properly managed. Being aware of how entrapment occurs allows you to take necessary precautions, ensuring a safer environment for everyone enjoying the water. Additionally, understanding the role of contrast ratio in projectors can help you select appropriate equipment for clear visibility in safety signage and instructional displays around water facilities.

Key Features of VGB Regulations for Basin Safety

The Virginia Graeme Baker Pool and Spa Safety Act (VGB) establishes essential safety requirements designed to prevent entrapment incidents in swimming pools and spas. One key feature is the mandatory use of anti-entrapment drain covers that meet strict performance standards, reducing the risk of entrapment caused by broken or loose covers. The act also requires all suction outlets to be equipped with multiple, independently operating safety devices, such as automatic shut-off systems or venting systems, to prevent a single failure from causing hazards. VGB regulations specify that pool and spa basins must have compliant drain systems, including properly designed drain covers and flow management devices. Additionally, facilities must document and maintain compliance records to demonstrate adherence to all safety standards.

Assessing Risks and Conducting Regular Inspections

You need to establish a consistent inspection schedule to catch potential hazards early. During inspections, look for areas where entrapment risks might develop and document your findings thoroughly. Keeping accurate records helps make certain of ongoing compliance and quick responses to any safety issues. Incorporating cost‑of‑ownership math into your maintenance planning can also help identify cost-effective solutions for safety upgrades.

Inspection Frequency and Schedule

Regular inspections are essential for maintaining safety and compliance at the basin, especially when evaluating entrapment risks and VGB requirements. You should establish a consistent schedule based on the level of risk, facility size, and usage patterns. High-traffic or complex basins may require more frequent checks, such as weekly or monthly, while lower-risk sites might suffice with quarterly inspections. Document each inspection thoroughly, noting any hazards or maintenance needs. Keep a detailed log to track trends and guarantee timely responses. Additionally, coordinate inspections around operational hours to minimize disruptions. Regularly reviewing and adjusting your schedule helps you stay ahead of potential issues, ensuring ongoing safety and compliance with all relevant regulations. Emphasizing preventative maintenance during inspections can further mitigate risks and improve overall safety.

Identifying Potential Entrapment Hazards

Evaluating risks and conducting regular inspections are crucial steps in identifying potential entrapment hazards at the basin. You need to examine all areas where swimmers can become trapped, such as drains, vents, and suction outlets. Look for signs of damage, corrosion, or loose fittings that could create hazards. Pay close attention to outdated or non-compliant components that may pose risks. Use a systematic approach to inspect every part of the basin, guaranteeing nothing is overlooked. Document your findings and note any irregularities or potential problems. Engaging staff in regular hazard assessments helps maintain a safe environment. Incorporating advanced inspection techniques can further enhance hazard detection and ensure compliance with safety standards. By proactively identifying these hazards, you reduce the risk of entrapment incidents and ensure compliance with safety standards. Regular inspections are your first line of defense in safeguarding swimmers.

Recordkeeping and Documentation

Effective recordkeeping and documentation are essential for evaluating risks and ensuring thorough inspections at the basin. By maintaining detailed logs of inspections, repairs, and hazard assessments, you create a clear history of safety practices. Regularly update records to reflect any changes in equipment or structure, which helps identify patterns or recurring issues. Proper documentation allows you to verify compliance with safety standards and VGB regulations. It also provides a reference during inspections, making it easier to spot potential hazards early. Consistent recordkeeping supports proactive maintenance, reduces the risk of oversight, and demonstrates your commitment to safety. Additionally, understanding anime culture and storytelling can enhance your approach to safety communication and training. Ultimately, thorough documentation helps you make informed decisions, prioritize repairs, and uphold the highest safety standards at the basin.

Designing Effective Anti-Entrapment Devices

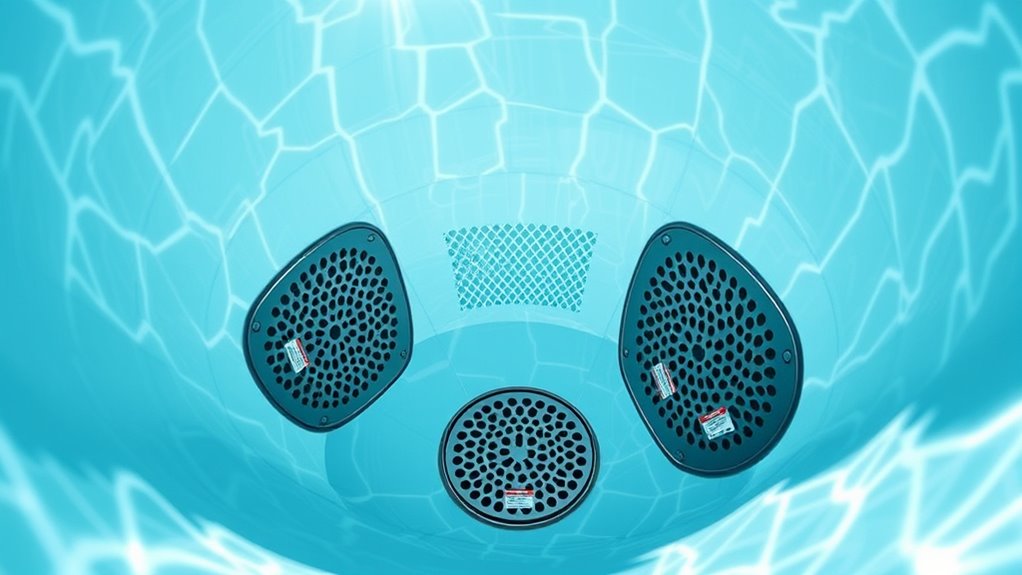

Designing effective anti-entrapment devices requires a thorough understanding of how swimmers interact with pool drain systems. You need to analyze flow dynamics and identify potential entrapment points. Consider the size and strength of the drain covers, ensuring they can withstand force without failure. Incorporate multiple layers of safety, such as safety vacuum release systems, to reduce suction risk. Use flow restrictors or modular covers to control water flow and minimize entrapment hazards. Always follow the guidelines set by the Virginia Graeme Baker Pool & Spa Safety Act (VGB Act) to ensure compliance. Collaborate with engineers and safety experts to optimize design features. Testing and reviewing device performance regularly helps confirm that your anti-entrapment systems remain effective and reliable, safeguarding swimmers at all times.

Installing and Maintaining Safety Grates and Covers

You need to guarantee safety grates and covers are installed correctly using proper techniques to prevent accidents. Regular inspections help identify wear or damage that could compromise safety, so make these checks routinely. Always choose approved materials that meet regulatory standards to maintain compliance and protect everyone at the basin. Incorporating risk management strategies ensures potential hazards are proactively addressed, enhancing overall safety.

Proper Installation Techniques

Proper installation of safety grates and covers is essential to guarantee they function correctly and prevent entrapment hazards. First, ensure the grate or cover fits securely within the designated opening, with no gaps or loose edges. Use the manufacturer’s specified fasteners and hardware, tightening them adequately without over-tightening, which could damage the equipment. Confirm that the grate is level and flush with the surrounding surface to avoid creating tripping or entrapment points. Follow the installation instructions precisely, paying attention to weight limits and load capacities. Regularly check for signs of corrosion, wear, or damage after installation. Proper installation not only complies with safety standards but also minimizes risks, ensuring the safety of all users around the basin. Additionally, understanding and applying proper installation techniques is crucial for long-term safety and compliance.

Regular Inspection Procedures

Regular inspections are crucial for ensuring safety grates and covers remain in prime condition and continue to prevent entrapment hazards. You should routinely check for corrosion, cracks, or any signs of wear that could compromise the integrity of the covers. Make certain all fasteners are secure and that the grate fits tightly without gaps. Look for any displacement or damage caused by debris, vandalism, or weather conditions. Use a checklist to document inspection findings and schedule repairs promptly. If you detect corrosion or damage, replace or repair the cover immediately to maintain safety standards. Regularly cleaning the grates also prevents debris buildup, which can obscure damage or weaken the structure. Conducting these inspections helps ensure that dog names or other animals do not inadvertently become trapped or injured. Consistent inspections help you identify issues early, ensuring ongoing compliance and the safety of everyone around the basin.

Selecting Approved Materials

Choosing the right materials for safety grates and covers is essential to maintaining their integrity and guaranteeing ongoing compliance. You must select approved materials that meet industry standards and VGB requirements. Using non-approved or substandard materials can compromise safety and lead to violations. Focus on durable, corrosion-resistant options designed for aquatic environments.

Consider these when selecting materials: 1. Confirm they are certified as compliant with VGB and anti-entrapment standards. 2. Choose corrosion-resistant metals like stainless steel or coated aluminum. 3. Ensure the materials are strong enough to withstand pool loads and environmental stresses. 4. Verify the manufacturer’s certification and quality assurance processes. Understanding narcissistic traits can help identify manipulative behaviors in others, which is crucial when managing safety and trust within community environments.

Implementing Proper Drainage and Pump System Safeguards

To effectively prevent entrapment hazards, you must implement thorough drainage and pump system safeguards that quickly remove water from the basin. Ensure your drainage system has multiple, reliable outlets to prevent water buildup, reducing suction risks. Install automatic shutoff devices that activate if water flow becomes abnormal, indicating a potential problem. Use properly sized and maintained pumps designed with anti-entrapment features, such as vents and covers, to prevent debris or body parts from being caught. Regularly inspect and test all safety mechanisms to ensure they’re operational. Keep drainage and pump systems free of obstructions, corrosion, and damage. Properly documented maintenance schedules and quick troubleshooting procedures are essential. Incorporate compliance with regulations to ensure safety standards are met and to reduce liability. These measures help maintain safe water levels and minimize entrapment hazards effectively.

Training Staff for Emergency Response and Safety Protocols

You need to guarantee your staff is ready to respond quickly and effectively in emergencies. Regular emergency response drills keep everyone prepared and identify areas for improvement. Providing clear safety protocol education helps prevent accidents and keeps the basin secure.

Emergency Response Drills

Have you ever wondered how quickly your team can respond to an emergency at the basin? Regular emergency response drills are essential to guarantee everyone reacts swiftly and correctly. These drills help identify gaps in your protocols and improve coordination. To make them effective, focus on these key areas:

- Simulate real-life scenarios to test response times and decision-making.

- Assign clear roles so everyone knows their responsibilities during an emergency.

- Use feedback sessions afterward to review what went well and what needs improvement.

- Update your plans regularly based on drill outcomes and evolving safety standards.

Safety Protocol Education

Effective emergency response relies not only on practicing drills but also on guaranteeing that every team member understands and consistently follows safety protocols. You need to regularly train staff on the specific procedures for entrapment prevention and VGB compliance. This involves clear communication of safety guidelines, so everyone knows their role during an incident. Conduct thorough training sessions that cover emergency steps, use of safety equipment, and reporting protocols. Encourage questions and discussions to reinforce understanding. Make safety protocol education ongoing, not a one-time event, so staff remain prepared and confident. When every team member knows and follows established safety procedures, response times improve, and hazards are minimized. This proactive approach helps protect lives and ensures compliance with regulatory standards.

Documentation and Record-Keeping for Compliance

Maintaining thorough documentation and accurate records is essential for demonstrating compliance with anti-entrapment and VGB regulations. Your records serve as proof during inspections and help identify areas needing improvement. To stay compliant, focus on these four key items:

- Installation Records: Keep detailed logs of equipment specifications, installation dates, and manufacturer information.

- Inspection Reports: Document routine inspections, maintenance activities, and any repairs performed.

- Training Logs: Record staff training sessions on safety protocols and equipment operation.

- Incident Reports: Track any safety incidents or entrapment events, including corrective actions taken.

Consistent record-keeping ensures you can quickly verify compliance and address potential issues proactively, keeping your basin safe and regulation-ready.

Collaborating With Regulatory Authorities and Experts

Collaborating with regulatory authorities and experts is essential for guaranteeing your basin remains compliant with anti-entrapment and VGB standards. By engaging with these entities, you gain valuable insights into evolving regulations, best practices, and technological advancements. Building relationships helps you stay ahead of compliance gaps and demonstrates your commitment to safety. Consider the following factors when working with regulators and experts:

| Aspect | Benefits | Actions |

|---|---|---|

| Communication | Clarifies requirements | Regular meetings and updates |

| Expertise | Informs risk mitigation | Consult specialists for assessments |

| Compliance | Ensures standards are met | Implement recommendations promptly |

| Feedback | Improves safety measures | Incorporate suggestions into plans |

Active collaboration ensures your safety measures are effective, compliant, and adaptable to changing standards.

Continuous Improvement and Upgrading Safety Measures

To guarantee your basin remains compliant with anti-entrapment and VGB standards, continuous improvement and regular upgrades to safety measures are essential. Staying proactive helps you identify vulnerabilities before they become hazards. Regularly review and update your safety protocols to incorporate the latest industry standards. Training staff on new procedures ensures everyone remains vigilant and prepared. Additionally, investing in advanced safety equipment can prevent accidents and entrapments. Consider these key actions:

- Conduct routine safety audits and inspections

- Upgrade to newer, more effective anti-entrapment devices

- Train staff on current safety practices and emergency responses

- Stay informed about evolving regulations and standards

Frequently Asked Questions

What Are the Common Signs of Entrapment Incidents in Water Facilities?

You might notice a person suddenly struggling, panicking, or calling for help, indicating potential entrapment. Other signs include a swimmer or diver being unable to free themselves, unusual movements, or visible distress near drains or suction outlets. Sometimes, you’ll see the person near the drain area, trying to escape. Respond quickly if you see these signs, as entrapment can happen rapidly and requires immediate intervention.

How Often Should Safety Devices Undergo Testing and Certification?

You should test and certify safety devices at least once a year, but more frequent inspections are prudent to catch issues early. Regular testing ensures your equipment works perfectly, preventing disastrous incidents that could be catastrophic. Don’t wait for a failure—stay ahead of problems by scheduling routine checks, ideally every 3 to 6 months, especially after repairs or upgrades, so your facility remains safe and compliant at all times.

Are There Specific Training Requirements for Emergency Responders?

Yes, emergency responders must complete specific training requirements. You should guarantee they receive initial training on safety protocols, rescue techniques, and equipment use. Regular refresher courses are essential to keep skills sharp and stay updated on new procedures. Additionally, responders should participate in drills and simulations periodically. By staying well-trained, you enhance safety and ensure quick, effective responses during emergencies, reducing potential injuries or accidents.

What Are the Consequences of Non-Compliance With VGB Regulations?

Ignoring VGB regulations is like steering into a storm—you risk hefty fines, legal action, and potential shutdowns that can sink your operations. Non-compliance can also lead to increased safety hazards, putting lives at risk and damaging your reputation. Staying compliant isn’t just a rule; it’s your anchor, ensuring smooth sailing and protecting everyone involved. So, prioritize regular audits and updates to keep your facility safe and compliant.

How Can Public Awareness Be Increased About Entrapment Hazards?

You can increase public awareness about entrapment hazards by organizing community workshops, distributing informative flyers, and utilizing social media campaigns. Encourage local pools and recreation centers to display clear safety signage and provide safety demonstrations. Partner with local schools to educate children about pool safety. Engaging the community through events and consistent messaging helps make people more aware of entrapment risks and the importance of adhering to safety measures.

Conclusion

So, despite all the safety measures and regulations, it’s ironic how many still assume accidents won’t happen. By staying vigilant, conducting regular inspections, and following VGB guidelines, you might just prevent a tragedy. Remember, safety isn’t a one-time effort but a continuous commitment. After all, the real surprise isn’t the hazards lurking in the basin — it’s how quickly things can go wrong when safety is overlooked. Stay alert; don’t let vigilance become your biggest surprise.