To maintain your pressure pool cleaner, regularly inspect for damage, especially on hoses, brushes, and wheels. Clean or replace filters and clear debris from intake ports to keep suction strong. Check and secure hoses and fittings, lubricate moving parts, and adjust pressure settings for ideal cleaning. Remove debris and store the cleaner properly during the off-season. Keeping up with these steps will help your cleaner perform better over time—more tips await if you continue exploring.

Key Takeaways

- Regularly inspect hoses, intake ports, and moving parts for damage, wear, or blockages, and clean or replace as needed.

- Clean and dry filters, intake ports, and hoses periodically to maintain optimal suction and performance.

- Lubricate joints, gears, and moving components with silicone-based lubricant to prevent wear and ensure smooth operation.

- Monitor and adjust pressure settings for optimal cleaning, and check the pressure gauge for accuracy regularly.

- Follow manufacturer guidelines for routine maintenance, safe servicing, and proper storage to extend your cleaner’s lifespan.

Regularly Inspect the Cleaner for Damage

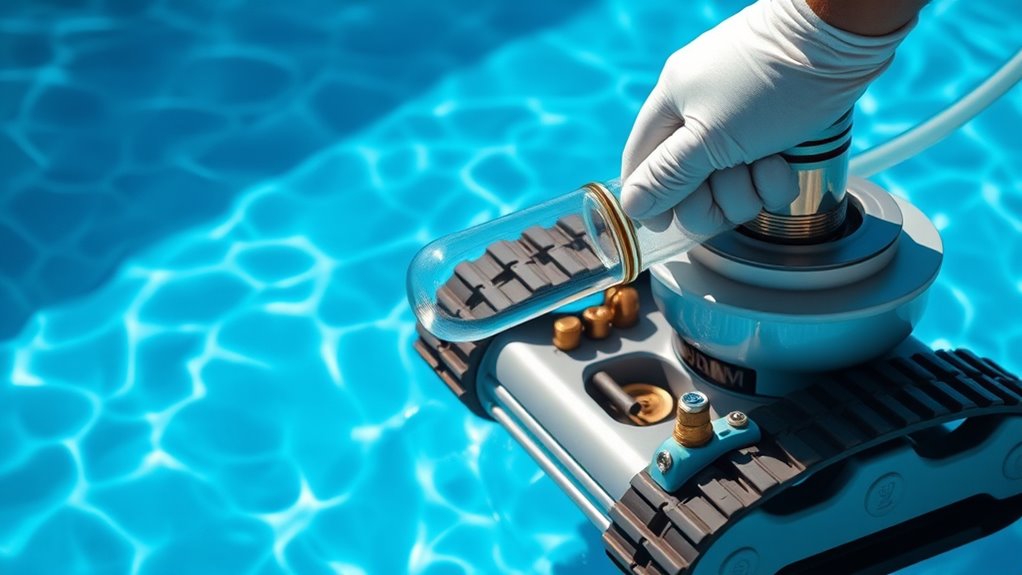

Regularly inspecting your pressure pool cleaner for damage is essential to keep it functioning effectively. Use an inspection checklist to identify signs of wear or damage early, preventing costly repairs and downtime. Check hoses for cracks, leaks, or loose connections, as these can reduce cleaning efficiency. Examine the brushes and wheels for excessive wear or missing parts, which can hinder movement and performance. Inspect the intake ports and nozzles for blockages or damage that could impair suction. Look for broken or frayed belts, and verify that all clamps and fittings are secure. Conducting these routine checks helps catch issues before they worsen, ensuring damage prevention and extending your cleaner’s lifespan. Regular inspections keep your pool cleaner running smoothly when you need it most. Additionally, understanding the materials and components, such as hose integrity, can help identify potential points of failure early and prevent costly repairs. Incorporating knowledge about pressure cleaner technology can also encourage establishing a regular maintenance routine, making inspections a consistent part of your pool care.

Clean the Filter and Intake Ports

You should regularly check the filter to guarantee it’s clean and functioning properly. Make sure the intake ports are free of debris so the cleaner can operate smoothly. Keeping these parts clear helps maintain ideal pressure and cleaning performance. Additionally, ensuring the device operates efficiently can be supported by understanding how filter replacement enables real-time adjustments and optimal performance. Regular maintenance, including timely filter changes, is essential for sustained effectiveness.

Regular Filter Inspection

To keep your pressure pool cleaner working efficiently, inspecting and cleaning the filter and intake ports is essential. Regular filter inspection guarantees maximum performance and prevents blockages that could strain the power supply. If the filter appears dirty or clogged, consider a filter replacement to maintain strong suction. Check for debris buildup around the intake ports and clear them promptly. Maintaining clean filters and ports helps extend your cleaner’s lifespan and keeps your pool sparkling. Remember to disconnect the power supply before servicing. Regular inspections also let you identify worn or damaged parts early, saving you from costly repairs down the line. Staying on top of filter maintenance ensures your pressure pool cleaner operates smoothly and effectively every time. Addressing trust issues with your equipment can prevent unexpected breakdowns and ensure consistent performance. Additionally, using appropriate replacement filters designed for your cleaner model can improve filtration efficiency and prolong its lifespan. Properly maintaining the filter system is crucial for optimal operation and longevity of your pressure pool cleaner, especially when considering the importance of suction power in maintaining cleaning efficiency. Regularly checking the filter media can also help you spot potential issues before they impact performance.

Clear Intake Ports

Have you checked the intake ports lately? Clogged or dirty intake ports can cause common pool cleaner problems like reduced suction or incomplete cleaning. Different types of pool cleaners, such as pressure-side or robotic models, rely on clear intake ports to function properly. To keep your pressure pool cleaner running smoothly, inspect and clean these ports regularly. Remove any debris or buildup that might hinder water flow. Sometimes, mineral deposits can clog the openings, so use a brush or a toothpick to clear stubborn blockages. Maintaining clean intake ports ensures your pool cleaner operates efficiently and prevents issues like frequent jams or poor coverage. Regular upkeep will extend your cleaner’s lifespan and keep your pool sparkling. Proper maintenance practices are essential for optimal performance and longevity of your pool equipment. Additionally, understanding the different types of pool cleaners can help you select the best maintenance approach for your specific model. Regularly inspecting and understanding cleaning techniques can help you troubleshoot issues more effectively, especially in systems where performance tuning plays a role in efficiency.

Check and Replace Hoses and Connections

Regularly inspecting your pressure pool cleaner’s hoses and connections is essential to guarantee ideal performance. During hose inspection, look for cracks, leaks, or signs of wear that could affect connection integrity. Damaged hoses can reduce suction and cleaning efficiency, so replace them promptly. Ensure all fittings and connections are tight and secure to prevent leaks and maintain proper water flow. Loose or worn connections can cause pressure loss and reduce cleaning power. Regular checks help catch issues early, saving you time and costly repairs later. Keep hoses flexible and free of kinks to avoid unnecessary stress on fittings. Proper maintenance of hoses and connections can prevent pressure loss, and considering regular replacement of hoses can further ensure your pool cleaner’s longevity. Additionally, understanding how heat pumps operate can help you optimize your pool’s temperature control system for better energy efficiency. Being aware of annuity features can also aid in planning your long-term financial stability, especially when preparing for retirement.

Lubricate Moving Parts as Needed

Keeping your pressure pool cleaner’s moving parts well-lubricated helps prevent wear and keeps everything operating smoothly. Regular lubrication tips include applying a silicone-based lubricant to joints, gears, and other moving components. Check the manufacturer’s guidelines to identify which parts need lubrication and how often. Moving parts maintenance is essential for preventing squeaks, stiffness, or jamming during operation. Avoid over-lubricating, as excess can attract debris and cause buildup. Use a small amount of lubricant and work it into the moving mechanisms carefully. If you notice any resistance or unusual noise, it’s a sign to re-lubricate or inspect for damage. Proper lubrication ensures your cleaner runs efficiently and extends its lifespan. Regularly maintaining lubrication is a simple step to keep your pressure pool cleaner performing at its best.

Monitor and Adjust the Pressure Settings

Monitoring and adjusting the pressure settings on your pressure pool cleaner is essential for peak performance. Proper calibration ensures the pressure gauge reads accurately, preventing over- or under-cleaning. To fine-tune, check the pressure gauge calibration regularly and compare it with a known standard. Adjust the valve as needed to increase or decrease pressure, ensuring ideal flow. Keep an eye on the pressure levels during operation and make small adjustments for consistent cleaning. If the pressure is too high, it might strain the motor; too low, and debris may not be cleaned effectively. Regularly inspecting and tuning these settings helps maintain efficiency and prolongs your cleaner’s lifespan.

- Test pressure gauge calibration periodically

- Make precise valve adjustments

- Watch for pressure fluctuations during operation

- Maintain recommended pressure levels

Remove Debris and Obstructions From the Cleaner

To keep your pressure pool cleaner working efficiently, you need to remove debris and obstructions regularly. Check and clear any blocked intake ports, remove external debris, and look for obstructions in hoses or brushes. Doing this guarantees your cleaner operates smoothly and avoids clogs or damage.

Clear Blocked Intake Ports

When your pressure pool cleaner isn’t operating efficiently, clogged intake ports are often the culprit. Debris blocking these ports can reduce water flow, affecting the pressure sensor’s accuracy and the cleaner’s performance. Start by inspecting the intake openings for leaves, dirt, or algae. Be cautious with the electrical wiring connected to the pressure sensor, ensuring it isn’t damaged during cleaning. Clear any obstructions carefully with a small brush or pin. Check for buildup that might hinder water flow. Maintaining clear intake ports helps maintain ideal pressure levels and extends your cleaner’s lifespan. Regularly cleaning these ports prevents issues before they escalate, ensuring your pool stays clean and your cleaner works efficiently.

Remove External Debris

External debris like leaves, twigs, and dirt can quickly accumulate on your pressure pool cleaner, hindering its performance. Regularly removing this debris prevents clogs and keeps your cleaner operating efficiently. Check the external filter types—whether fine mesh or coarse mesh—and clear out any trapped debris. Doing so helps maintain proper pool water chemistry by preventing debris buildup that can affect water clarity and chemical balance. Always inspect the cleaner’s intake and external surfaces, removing any obstructions that could impede movement or suction. Keeping the external parts clean ensures better water flow and prolongs the lifespan of your cleaner. Make this a routine part of your pool maintenance to keep your pressure pool cleaner running smoothly and effectively.

Check for Obstructions

Regularly inspecting your pressure pool cleaner for obstructions is essential to guarantee peak performance. Obstructions can hinder the cleaner’s movement and reduce cleaning efficiency. Start by checking the hose inspection to ensure no kinks or blockages are restricting water flow. Look for debris buildup in the intake or nozzle areas that may impede operation. Remove any debris or obstructions you find to keep the cleaner running smoothly. Regular debris removal prevents clogs that can damage the equipment or decrease suction power. Also, inspect the brushes and wheels for tangled debris or obstructions that could slow down or stop the cleaner. Keeping these parts clear helps maintain ideal performance and prolongs the life of your pressure pool cleaner.

- Check the hose for kinks or blockages

- Clear debris from the intake and nozzle

- Remove tangled debris from brushes and wheels

- Ensure the hose connection is secure

Store the Cleaner Properly During Off-Season

To guarantee your pressure pool cleaner remains in good condition during the off-season, it’s important to store it properly. Proper storage involves cleaning and drying the unit thoroughly to prevent mold and corrosion. Before winterization, disconnect all hoses and remove any debris or water that could freeze and cause damage. Store the cleaner in a cool, dry place away from direct sunlight and harsh weather. Keep it in a secure spot where it won’t be knocked over or damaged. Ensuring proper storage during the off-season helps maintain its performance and extends its lifespan. Follow these winterization tips to protect your investment and make startup easier when you’re ready to use it again next season.

Test the Cleaner’s Performance Periodically

After storing your pressure pool cleaner properly for the off-season, it’s important to check its performance periodically to guarantee it remains ready for use. Regular testing helps identify issues like cleaning chemical compatibility problems or battery maintenance needs before the season starts. To do this effectively, observe how well it navigates and cleans your pool, listen for unusual noises, and check for debris buildup. Keep an eye on the battery’s charge level and ensure it holds a proper charge. Also, verify that the cleaner’s brushes and wheels move smoothly. Conducting these inspections shortens repair time and keeps your cleaner in top shape.

- Check cleaning chemical compatibility to prevent damage

- Test battery maintenance and charge retention

- Observe cleaning efficiency and navigation

- Inspect brushes and wheels for smooth operation

Follow Manufacturer’s Maintenance Recommendations

Following your pressure pool cleaner’s manufacturer’s maintenance recommendations guarantees it stays in peak condition and functions effectively. Always check for guidance on chemical compatibility to prevent damage from harsh pool chemicals. Proper maintenance may include cleaning filters, inspecting hoses, and replacing worn parts as advised. When storing your cleaner, follow recommended storage solutions to avoid deterioration; store in a cool, dry place away from direct sunlight and chemicals. Adhering to these guidelines ensures longevity and reliable performance. Regularly reviewing the manufacturer’s instructions helps you stay on top of maintenance tasks and avoid costly repairs. By following these recommendations, you’ll keep your pressure pool cleaner operating smoothly, saving you time and money while maintaining a clean, healthy pool environment.

Frequently Asked Questions

How Often Should I Perform a Full Maintenance Check?

You should perform a full maintenance check on your pressure pool cleaner at least once a season, or every 3 to 4 months. During this time, do routine inspections of all components, including hoses and filters, and consider component upgrades if parts show signs of wear. Regular maintenance guarantees your cleaner runs efficiently, prolongs its lifespan, and keeps your pool sparkling clean.

Can I Upgrade Parts for Better Cleaning Efficiency?

You can definitely upgrade parts to improve your pressure pool cleaner’s cleaning efficiency. By replacing worn or outdated components like the brushes, wheels, or nozzles with higher-quality or specialized parts, you boost performance. Upgrading parts allows your cleaner to navigate more effectively and pick up debris better. Always check compatibility before making upgrades, and consider consulting your manufacturer for recommended parts to guarantee ideal cleaning results.

What Signs Indicate the Cleaner Needs Professional Repair?

If your pressure pool cleaner isn’t working properly, look for signs like excessive pool debris or if it starts to leak cleaner. These issues often mean it needs professional repair. You might notice the cleaner isn’t moving correctly or it’s losing pressure, which points to internal problems. Don’t ignore leaks or persistent debris, as they can worsen the situation. Contact a professional to diagnose and fix the issue to keep your pool spotless.

Is It Safe to Use the Cleaner During Rainfall?

Rainfall safety is important when using your pressure pool cleaner, as heavy rain can cause electrical issues or damage. It’s best to avoid running the cleaner during or immediately after rainfall to prevent malfunctions. Regular cleaner maintenance can help guarantee it operates safely when you do use it. If the weather is rainy, delay your cleaning schedule until the rain stops, protecting both your equipment and your pool’s condition.

How Do I Troubleshoot if the Cleaner Isn’T Moving Properly?

They say “a stitch in time saves nine,” and that’s true for troubleshooting your pressure pool cleaner. If it isn’t moving properly, first check the pressure hose for kinks or leaks. Then, inspect for debris obstruction around the cleaner’s intake or brushes. Clearing these blockages and ensuring the pressure hose is secure often restores proper movement, saving you time and keeping your pool sparkling clean.

Conclusion

By regularly inspecting and maintaining your pressure pool cleaner, you’ll catch issues before they become costly. Clean filters, check hoses, and store it properly during off-season—these simple steps keep it running smoothly. Funny enough, just when you think you’ve done enough, a quick performance test might reveal it’s ready for a surprise swim. Stay vigilant, follow the manufacturer’s advice, and your cleaner will be your pool’s best friend season after season.